Dual Hydraulic Failure

Tutorial for handling of a Dual Hydraulic Failure in the A320 family.

System Overview

The Airbus A320 has 3 different hydraulic systems called GREEN, BLUE and YELLOW system. Each system has its own Reservoir and the normal system pressure is 3000 psi.

System Description

| System | Description |

|---|---|

| GREEN | Is being pressurized by an Engine Driven Pump (EDP) which is connected to Engine N1. Hence the Green EDP can only produce pressure when the engine is running. |

| BLUE | Is being pressurized by an Electric Pump. In an emergency the blue system can also be pressurized by the RAM Air Turbine (RAT). |

| YELLOW | Is being pressurized by an Engine Driven Pump (EDP) which is connected to Engine N2. As a backup power source, an electriv driven pump is also available on the ground and is used for short term usage only. If this pump fails, there is a handpump with which the cargo doors can be opened. |

| PTU | Power Transfer Unit. Is built in to allow system pressure transfer (not fluid transfer) from the yelow to green system and vice versa. |

Before going into the complicated procedure it is worth looking at the Hydraulic Distribution Chart below.

Hydraulic Distribution Chart

Overview

Warning

A dual hydraulic failure, especially the GREEN + YELLOW (G+Y HYD ) means a lot of important systems fail. Flaps, Landing Gear, THS, Reversers, Nosewheel Steering, Normal and Alternate Brake System, Yaw Damper fail.

Luckily there are backup system available. The landing gear can be extended by gravity extension. Even though the Flaps are lost completely, the slats will be able to be extended by the remaining blue hydraulic system. One very important control surface, the Trimmable Horizontal Stabilizer (THS) is lost as well. However in Alternate Law there is the so called „Neutral-Reference“ being used by the ELAC, changing the position of the elevators to artificially „trim“ the aircraft. This function is lost however once the landing gear is lowered and the aircraft goes into direct law.

Going through this failure poses a huge challenge for a pilot, since the autopilot stops working and the aircraft going into alternate law. Also quite a few control surfaces are lost, making the aircraft feel different and somewhat sluggish.

In the F/CTL SD page you can see how certain flightcontrol servo actuators are inoperative. For example you can see that spoiler pairs 1,2,4 and 5 are inop. The ailerons and elevators are fully functional because each pair has a working blue hydraulic actuator. The THS is completely inoperative since both actuators lost their hydraulic power. The rudder is still functional because the Blue hydraulic actuator still has hydraulic power.

Situation Handling

So how do we handle this particular dual hydraulic failure? As always we apply the basic principle:

1. Aviate

- Check active control law

- Pitch, Power, speed, speedbrake

- Optimum use of AP and A/THR

2. Navigate

- Terrain

- Altitude

- Navigation

- Radar vectors

3. Communicate

- Info ATC

- Comm-Check

- Mayday

Once that is completed, we verify the malfunction via the ECAM, Panels/Pushbuttons. Then we check if it is time-critical. If it is we might do a preliminary decision making by flying towards a suitable airport.

Then we Perform the Procedure (Normally ECAM, sometimes however QRH). In our case with the G+Y HYD failure we do the ECAM procedure.

ECAM Procedure

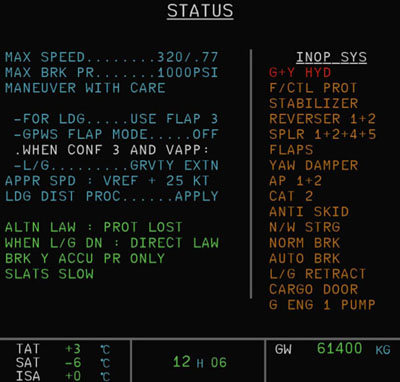

Once we get to the STATUS page we need to take a deep breath and not get overwhelmed by the amount of inoperative systems shown.

We start at the left side and go through the list of actions to be taken or limits to be respected. After that, we look at the right side of the INOP SYS list and take note of all the inoperative systems.

Once that is completed we „Remove Status“ and start our Decision making.

For a detailed explanation and an example of an ECAM Procedure please click the following link.

Decision Making

Correct flow of the decision making process.

1. Facts

- What minimum Runway Length do we need?

- What weather Minimuns do we need?

- What minimum fire fighting/rescue service do we need?

2. Decision

- Since we need to land ASAP we use the first available option (airport) that allows a safe landing according to our fact-finding

3. Execute

- We then fly the necessary procedure

Note

It is advisable to first do a normal approach briefing followed by the abnormal briefing.

Here we would mentioned the following things:

- ALTN Law, when Landing Gear down DIR Law

- A/THR Off before DIR Law becomes active

- Stabilizer inoperative, so after Landing Gear down no more Elevator Neutral Reference

- Establish Config 3 first and Vapp (selected mode to avoid Gsmini)

- Then use Gravitiy Gear Extension Procedure (before G/S interception)

- Pitch will be higher due to missing flaps

- In case of GA, L/G retraction Inop, L/G Doors remain open

- In case of Landing, reverser inop, Nose Wheel Steering inop

- Accumulator Brake pressure only (max Brake Pressure 1000 PSI)

- After Landing we might need to go into Evacuation Procedure

Video Tutorial

In this video I am coping with a dual hydraulic failure (Green and Blue System). This video was taken from a Twitch Livestream.

FSL A320 FNX A320

Warning

ONLY for FLight-Simulation!